Hardware & Metal

Stamping & Die Cutting: Stamping and die cutting are essential manufacturing processes used to create precise and intricate shapes from various materials, such as metal, plastic, paper, and fabric.

Stamping:

Stamping involves pressing a die, or a shaped tool, into the material to deform it and create the desired shape. It is commonly used in metalworking to produce parts for various industries, including automotive, aerospace, and electronics. Stamping is highly efficient for producing large quantities of consistent and high-quality parts.

Die Cutting:

Die cutting, on the other hand, uses a die to cut specific shapes from sheets of material. This process is widely employed in industries like packaging, textiles, and paper products. Die cutting allows for the creation of intricate designs and patterns with precision and speed. It is also commonly used for creating labels, gaskets, and decorative elements.

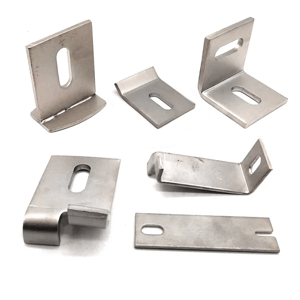

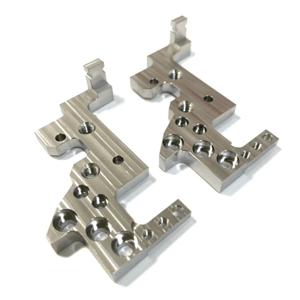

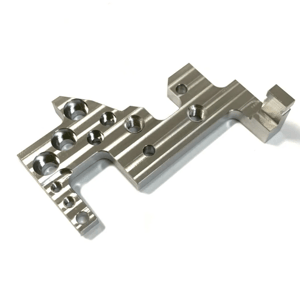

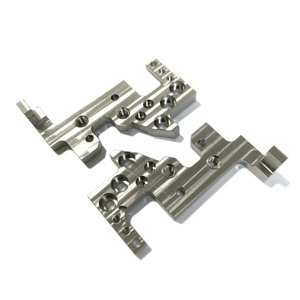

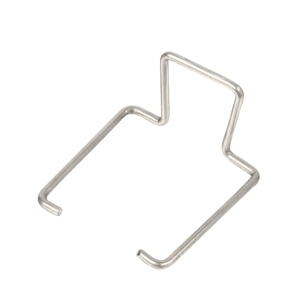

Bracket

.png?width=300&height=300&name=brackets%203%20(1).png)

.png?width=300&height=300&name=brackets%203%20(2).png)

Washer

Spacer

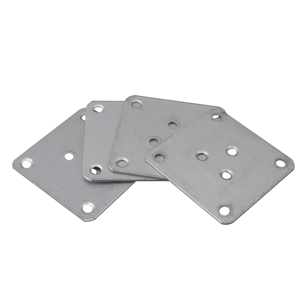

MOUNTING PLATE

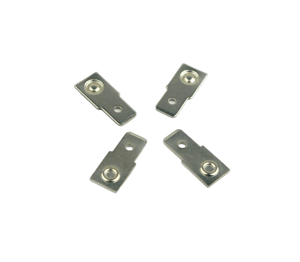

Cupped welding disk

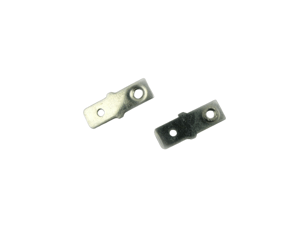

Cold Pin

.png?width=300&height=300&name=terminal%20pins%20(1).png)

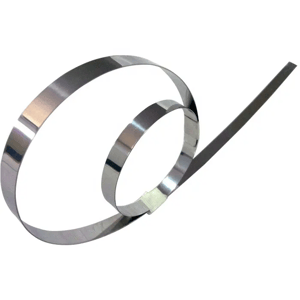

METAL STRIP

Lathe Parts: Lathe parts are products manufactured by lathe processing. According to different types of lathes, lathe parts are divided into many types, including automatic lathe parts, CNC lathe parts and instrument lathe parts, etc. These products can use different kinds of hardware materials, such as copper, iron, aluminum and stainless steel. The application range of lathe parts is very wide, covering many industries such as electronic appliances and hardware tools. Its main feature is precision machining, and its tolerance can reach plus or minus 0.01 mm, or even higher precision levels. This precision makes lathe parts essential and critical components in many industries.

Fasteners: Fasteners are a type of mechanical parts used for fastening connections and are widely used. It usually includes the following parts: bolts, studs, screws, nuts, self-tapping screws, washers, retaining rings, pins, rivets, welding nails, etc.

SUS Strips & Tubes: 1) There are many types of stainless steel belts with wide range of uses: SUS201, SUS301, SUS304, SUS304L, SUS305, SUS309S, SUS310S, SUS316L, SUS317L, SUS321, SUS329J4L, SUS409L, SUS436L, SUS439, SUS443, SUS444, SUS 445L1, SUS445L2, SUS446, Alloy 600, Alloy 625, Incoloy 800, Incoloy 825,Incoloy 840, SUS890L. 2) Stainless steel pipe is a hollow long circular steel. Common materials are: SUS201, SUS301, SUS304, SUS304L, SUS305, SUS309S, SUS310S . 40, SUS890L.

Spring & Wire forming: A spring is a mechanical part made of elastic material that deforms under the action of external force and returns to its original shape after the external force is removed. Common ones include: compression springs, tension springs, torsion springs, etc. Wire forming products mainly bend steel wire, iron wire, stainless steel wire and other wires into flat or three-dimensional shapes through straightening, folding, cutting, etc.

compressing Spring: Compression spring (compression spring) is a coil spring that bears axial pressure. Its shapes include: cylindrical, conical, convex and concave shapes, as well as a small amount of non-circular shapes, etc. There is a gap between the turns of the compression spring. With a certain gap, the spring shrinks and deforms when subjected to external load, storing deformation energy.

.png?width=300&height=225&name=compressing%20Spring%20(1).png)

Tension Spring: Tension springs (tension springs) are coil springs that bear axial tension. Tension springs are generally made of circular cross-section materials. When not under load, the coils of a tension spring are generally tight and there is no gap between them. It uses the elasticity (tension) after stretching to control the movement of parts, store energy, measure force, etc. It is widely used in machines and instruments. The hook types include side hook extension spring, long hook extension spring, British hook extension spring, German hook extension spring, semicircle hook extension spring, duckbill hook extension spring, etc. Its materials include stainless steel, piano steel, high carbon Steel, phosphor bronze, beryllium copper, oil tempered alloy spring steel, etc.

.png?width=300&height=300&name=Tension%20Spring%20(1).png)

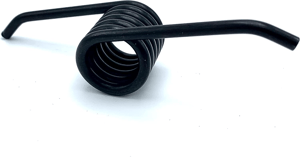

Torsion spring: Torsion springs (torsion springs) use the principle of levers to twist or rotate soft and tough elastic materials, giving them great mechanical energy. It is a spring that withstands torsional deformation, and its working part is also surrounded either tightly or separately. The end structure of the torsion spring is processed into torsion arms of various shapes, from single torsion to double torsion, and even various torsion bar deformations, which can be formed according to the design. Torsion springs are often used in balancing mechanisms in machinery and are widely used in industrial production such as automobiles, machine tools, and electrical appliances.

.png?width=300&height=400&name=Torsion%20spring%20(1).png)

U Shape wire formingU: Profile wire forming is to bend steel wire, iron wire, stainless steel wire and other wires into a U-shaped shape by straightening, bending, cutting, etc.

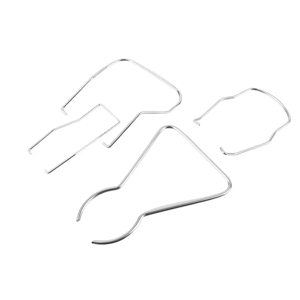

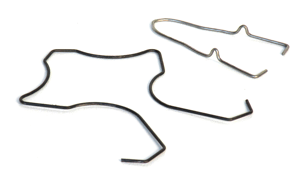

Multi Shape wire forming: Multi-shape wire forming is to bend steel wire, iron wire, stainless steel wire and other wires into multiple shapes through straightening, bending, cutting, etc.

.png?width=300&height=300&name=Multi%20Shape%20wire%20forming%201%20(1).png)

.png?width=300&height=300&name=Multi%20Shape%20wire%20forming%202%20(1).png)

S Shape wire formingS: Shape wire forming is to bend steel wire, iron wire, stainless steel wire and other wires into an S shape by straightening, bending, cutting, etc.

Hose Clamp: The clamp is a connecting device that connects grooved pipe fittings, valves and pipeline accessories. It is used to tighten the connection between quick connectors. Generally, the joints are equipped with gaskets, rubber, silicone and PTFE. It has good performance, high sealing degree and easy installation.

Aluminum Material & Pipe: Aluminum products are made of aluminum and other alloying elements. The main metal element is aluminum, and some alloying elements are added to improve the performance of the aluminum. The aluminum tube is a type of non-ferrous metal tube. It refers to a metal tubular material that is extruded from pure aluminum or aluminum alloy and is hollow along its entire longitudinal length. According to the shape, it is divided into square tube, round tube, pattern tube and special-shaped tube. Tube, Universal Aluminum Tube, which is characterized by corrosion resistance and light weight.